- The New Materials Design and Application Awards encourages material developers and designers to come together and take on newer challenges.

- The two key directions of China’s new materials design trends are repurposing the original materials for a new application and innovating with hybrid materials.

- The gap between the requirements of designers and the existing capability of material producers holds back many ideas.

The new materials industry in China has witnessed tremendous growth in the past decade, fuelled by market demand from key domestic industries. Since the 12th national Five-Year Plan (2011-2015), the Chinese government has prioritised the development of new materials as a “strategic emerging industry”. Furthermore, the “Made in China 2025” strategic plan, a key component of the 13th FYP (2016-2020), saw the issuing of supportive policies to promote the new materials industry, accompanied by a significant surge in funding to advance research in materials science, which had quadrupled from 2008 to 2019. Applicability, quality, sustainability, and novelty were established as the main focuses. Leveraging the new functionalities and enhanced performances offered by these new materials, Chinese designers have been pushing the frontiers of imagination with their real-world applications.

In 2020, swissnex China was invited to judge The New Materials Design and Application Awards hosted by Neuni Group, one of the leading companies pushing new material research and design in China. The NMDAA tries to bridge the gap between new material development and design application. It challenges designers and corporations to decipher the world of material. In reviewing all the applicant’s proposals, we found that, in general, China’s new materials design trends can be summarised into two key directions:

One is to use existing materials, where the designer repurposes the original materials for a new application. For this trend, there are also multiple paths to take, the most basic of which is to regenerate the original materials.

In the instance of the Tea and Starch Food Packaging project by Xiaoyan Xing, Jia Wan, Wenqian Li, and Tongyao Liu, waste tea leaves were made into packaging material for instant food.

Picture from Project Proposal by Xiaoyan Xing, Jia Wan, Wenqian Li, and Tongyao Liu. Image Source: Neuni Group

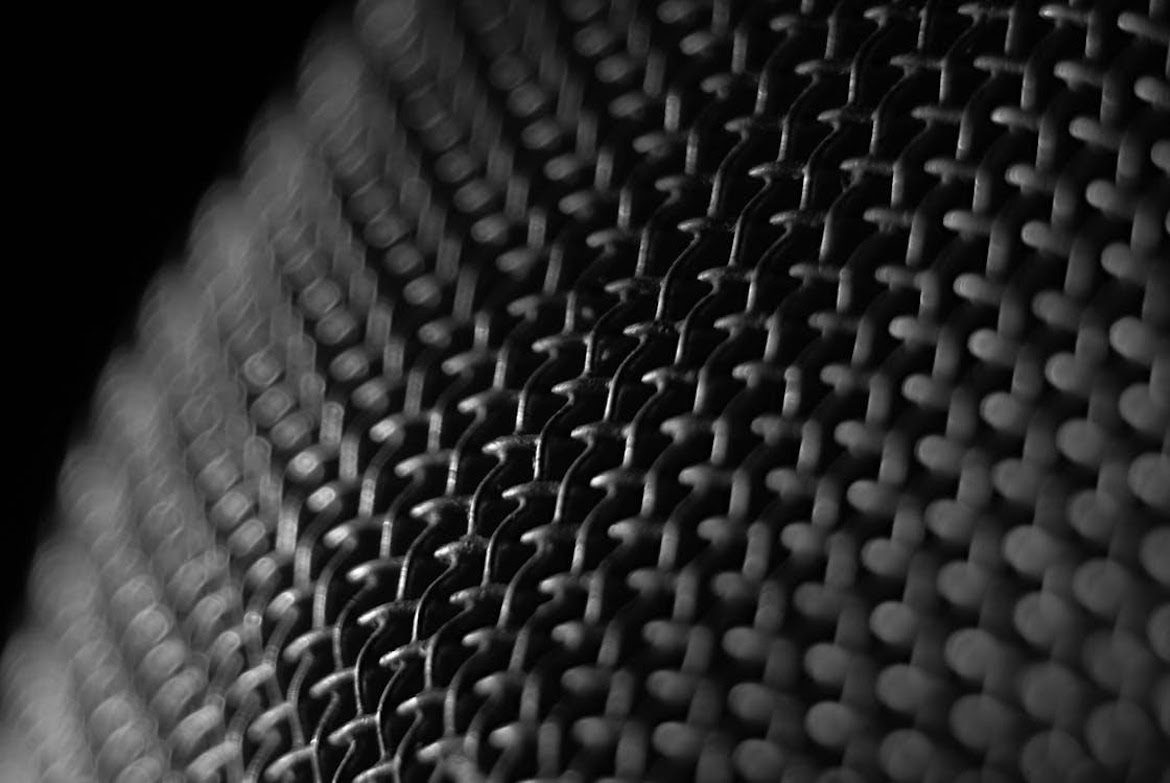

Another path is to innovate with hybrid materials. The Repleasure by Yilian Chen provides one of the best illustrations here. This project starts with the collection of several tons of discarded balloons from a balloon production factory and then mixing them with pbat Granulation. After granulation, they are put into a twin-screw extruder to draw the thread, to be used for weaving.

Repleasure Project by Yilian Chen. Image Source: Neuni Group

Finally, extracting special components offers further possibilities. In the Graft project by Qiyun Deng, she discovered the PLA (plastic polylactic acid) could replace traditional plastics. It is derived from plants such as corn, sugar cane, or cassava and can be completely biodegraded through industrial composting. In Graft, she transformed the PLA into (Grafting) series tableware to solve the pollution caused by disposable products.

Graft by Qiyun Deng. Image Source: Neuni Group

The other general trend is to develop completely new chemical substances. As an example, Kanghui Petrochemical in cooperation with the Dalian University of Technology has independently developed the PBS-type biodegradable polyester. As with the partnership that led to the PBS polyester, many new materials producers work with universities in the research and development process to bridge the gap with academic-industry collaborations. Sustainability and ecology usually form the foundation of these industrial innovation initiatives.

However, China’s new materials industry still needs to address a number of challenges in its way. In regards to the design process, the traditional design process involves coming up with an idea, prototyping it, and moving it into mass production. However, due to the gap between the majority of designers and material producers, many ideas are stopped short due to a lack of tools and knowledge of manufacturing or a lack of material and technology.

As for the application, China’s research and development cycle of new materials are generally quite time-consuming, and the commercialisation speed often cannot satisfy the market needs, resulting in high input cost and investment risk. Additionally, the development of high-end materials is still in its infancy, and many materials still rely on imports.

NO COMMENT