- A maturing tech sector in India is focussed on resilient innovations rather than constant Jugaad. The new tribe of Indian innovators may use the principles of Jugaad in the process of innovation, but they go beyond and make sure their product or service can operate in multiple environments as the context keeps changing.

- With two decades of grassroots level experience, SELCO has built up a database of innovative processes and solutions – technological, financial and business model-oriented that have the potential to be replicated in other regions and contexts, with appropriate customisation.

- Jidoka, an AI enabled manufacturing service for anomaly detection, has made great strides in assisting quality control processes in marquee manufacturing setups.

Over the past decade management gurus have sung the praises of Jugaad, a word coined in India to describe hyper-local innovations that are often very creative in the way they tackle the problem at hand. In keeping with the context of these problems, the Jugaad solutions are often quick to implement with material available and are often very affordable in nature. There have been many attempts to convert some of these innovations into standalone products and also to train companies to build an innovation culture that encourages people to come up with solutions on their feet instead of passing the buck. However, the need for Jugaad itself is symptomatic of a lack of Resilience – with a capital ‘R’ – in the underlying systems and products that people deal with.

This constant need to innovate at the point of failure has led to a tribe of problem solvers that thinks in terms of Resilience built into their products themselves. Here we will highlight some of the solutions that address paradigm shifts that will be upending our society and our businesses in the near future: Sustainable energy and Automation.

Resilience in energy generation

With two decades of grassroots level experience, SELCO has built up a database of innovative processes and solutions – technological, financial and business model-oriented that have the potential to be replicated in other regions and contexts, with appropriate customisation. The goal within the SELCO Foundation has been to effectively and efficiently ensure adaptation or replication of solutions suited to specific contexts rather than attempting a ‘cookie-cutter’ approach to scale up.

SELCO has set up many such innovations focussing on energy access and livelihood generation. Some of them are:

- Integrated Energy Centres – Entrepreneur led solar energy centre that brings energy to the community and is also driven by local entrepreneurs

- Solar-powered sewing machine – a simple engineering innovation that increases household income and keeps ROI very high

- SELCO service camps – enables people to service their SELCO products at service camps in remote areas, bringing down the cost of customer service while keeping customer trust high

- DC refrigerators – allows for storage of medicine in remote areas and provide an increased source of income to petty shops

- Solar-powered hospitals – detailed further below

Solar-powered sewing machine. Photo: SELCO

Ensuring access to reliable and quality health care infrastructure to all is critical to poverty alleviation and equitable development. As the country continues to fight against the pandemic, the Ministry of Health and the SELCO Foundation have taken up one of the largest programs for upgrading public health facilities with solar energy.

Setting up a mini solar power grid in a remote location in India. Photo: SELCO

Through this initiative, in the first phase, sustainable solar energy solutions and efficient medical equipment will be integrated across 1278 healthcare facilities in 10 chosen districts within the states of Karnataka, Manipur, Meghalaya, Nagaland and Odisha. Solar energy will be used to strengthen immunisation, maternal and child care, as well as basic diagnostics and critical care. Energy efficiency drive in these facilities will optimise the solar energy requirement and reduce energy consumption by 50-60%. The initiative will directly impact a population of more than 5.7 million people that depend on the public health value chain across the 10 districts.

With improved energy reliability and access, the interventions will help reduce out-of-pocket expenses for end-users, improve staff retention levels especially in remote and vulnerable contexts, and change end-user perceptions on the value of public health facilities, increasing footfalls and usage. The program will be a collaboration between government agencies, health facilities and staff and health sector NGOs to ensure better delivery of health care.

Harish Hande, CEO of SELCO Foundation, says “India, through multiple initiatives like these, is well on its way to becoming a beacon of climate innovation for the developing world.”

Resilience in precision manufacturing

Jidoka, an AI-enabled manufacturing service for anomaly detection, has made great strides in assisting quality control processes in marquee manufacturing setups. It was started by technologists educated in IITs and Cornell, who realised that the constant churn in people meant that important quality control measures would often fail due to constant issues in training or skill.

The demand for manufacturing has been growing consistently over the last decade, and Indian manufacturing is well into the race to be able to compete in the global market. But, meeting the growing demand with quality products is easier said than done.

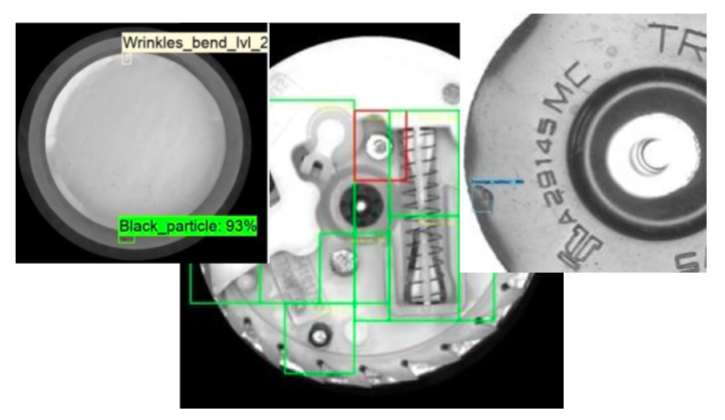

A sample set of how Jidoka’s AI-enabled system identifies anomalies in a manufactured item. Photo: Jidoka

Most organisations that rely on either manual or machine vision-based defect detection cannot manage the inspection of 100% of production units. It is mostly done at sampling or at a batch level. Wherever a 100% or 200% inspection is done manually there is a significant fallout in terms of false positives and a high risk of a bad product getting shipped to the consumer.

Jidoka’s state-of-the-art automated cognitive quality control solution combines the power of artificial intelligence with automation and machine vision to enhance the quality and efficiency of QC in the manufacturing process

Computer Vision can be used in manufacturing for detecting surface level anomalies, even on a minuscule level of 0.1 mm or lower. By sizing for the right resolution cameras, the right lighting environment, the best possible images of any product can be recreated, be it a shiny metal surface, a black rubber object or a small needle. The advancements in Deep Learning algorithms combined with industry-specific learnings, help companies to identify defects on the digital twins that are the raw images. It is then a continuous improvement journey for organisations, constantly improving the AI models by retraining, in order to keep up with their manufacturing process drifts. This method can improve the detection accuracy to more than 99% while also keeping the false positives very low – in the order of 5%, something that is impossible to achieve with both manual inspections or through conventional machine vision programming.

This solution combination of industrial automation, integrating cameras and the use of Deep Learning AI for automating visual QC checks is gaining increasing acceptance among manufacturing companies across all tiers and across industries such as automotive, FMCG, pharma, packaging, printing and electronics.

Jidoka has been able to achieve the below metrics with almost all their implementations:

- Quality Control – 30 to 40% reduction in false rejections, 10% improvement inaccuracy

- Quality Assurance – 15% reduction in PPM by providing analytics to improve the manufacturing process

- Human Resource – 5 to 10% resource reduction, lower-skill & training requirement, reduction in HR costs -from 1 to 5%

- Production planning and control – 33% increased speed of inspection

- ROI realisation in 12-18 months

This results in a better quality of products manufactured (greater accuracy of defect detection) and increases in bottom lines, savings from avoiding wasteful rejection, and earnings from greater throughput.

Working with the tribe of resilience innovators

This newer tribe of innovators in India focuses much more on finding solutions to problems that build greater resilience rather than a stop-gap solution to the problem in front of their eyes. While they may use the principles of Jugaad in the process of innovation, they don’t stop there and make sure their product or service can operate in multiple environments as the context keeps changing.

Any business around the world can have a high degree of confidence in working with or partnering with such organisations and entrepreneurs.

(For further details on SELCO, please contact info@selcofoundation.org. For further details on Jidoka, please contact vinodh@jidoka-tech.com. Extracts and quotes from articles by SELCO foundation have been used in this article.)

NO COMMENT