- India has an ambitious goal of installing 175GW of renewable energy by 2022 out of which 40 GW has been targeted to come from rooftop systems. Solar power represented 10% of the total installed power capacity in India as of Q3 2020.

- Companies around the globe have started using deep-data analytics, and with the help of Artificial Intelligence and Machine Learning, they have started optimising their operations and maximising their revenue.

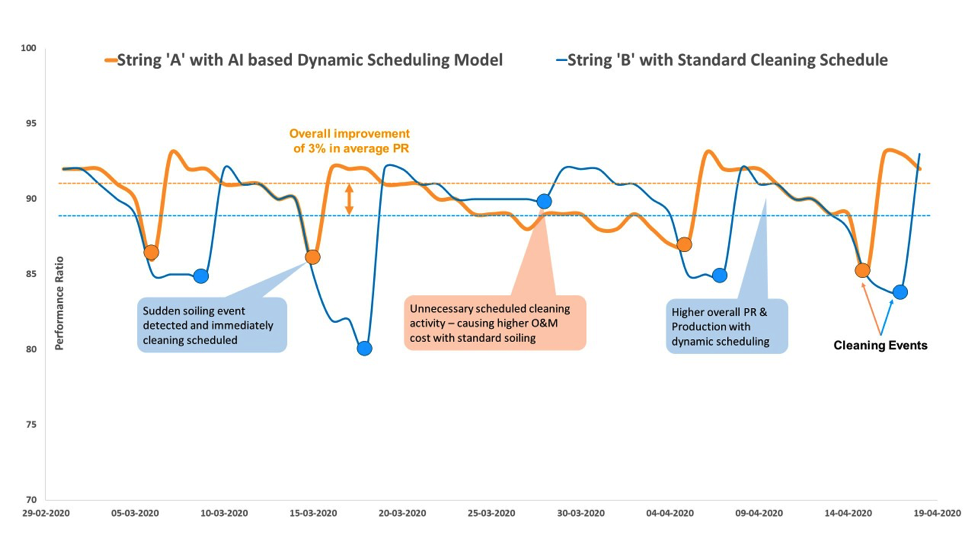

- Advanced AI models use dynamic pollution modelling and climate change factors to estimate realistic energy production, suggest dynamic cleaning schedules, accurately intercept shading losses, and monitor the electrical characteristics of your plant to predict its behaviour.

India has an ambitious goal of installing 175GW of renewable energy by 2022 out of which 40 GW has been targeted to come from rooftop systems. Analysing this opportunity, many big companies have increased their focus on rooftop installs who were primarily focused on ground mounted solar installs.

Renewable power installations (excluding large hydro projects) held a 24.2% share of the country’s overall power mix and stood at about 90.6 GW as of September 30, 2020. This was a marginal increase from last quarter’s 89.5 GW. In the same period the previous year, the country had about 85.3 GW of renewable installations (excluding large hydro). In terms of market share, solar power held about 9.9%, wind power held around 10.2%, bio-power held 2.7%, small hydropower held 1.3%, and waste-to-power projects held a meagre 0.05% share. During the quarter, cumulative solar installations rose marginally to 37.4 GW, up from 36.9 GW in the previous quarter. According to Mercom India Solar Project Tracker, India added about 433 MW (preliminary figures) of solar capacity in Q3 2020, and cumulative solar installations stood at around 37.4 GW at the end of Q3 2020. Solar power represented 10% of the total installed power capacity in India as of Q3 2020.

Focusing on the problems with the solar plants (constructed and operational pre-lockdown), here is a quick summary of COVID-19 impact:

1. Many Commercial and Industrial (C&I) solar rooftops have been shut down because these buildings (factories, schools etc) are shut.

2. Such C&I projects with the Operating Expenses (OPEX) model have choked the revenue of Independent Power Producers (IPPs).

3. Projects built under government tenders have Performance Ratio guarantee commitments but due to lack of manpower or restricted movements, cleaning schedules have been affected.

4. Some plants which are still operational during the lockdown had maintenance scheduled post March 25th, but again, they could not be served on a timely manner leading to further decreasing performance of these sites.

5. Rooftops got very little share of the voice, focus was diverted towards utility scale plants.

India installed 1700MW of rooftop capacity in 2019. 90% of this capacity installation came from the Commercial and Industrial (C&I) segment. Although developers are worried that all facilities are shut down because of the recent pandemic-control measures, they appear to be taking steps to ensure that revenues continue to flow. On the other hand, the remaining 10% of the smaller residential rooftop installations are predominantly accounted for by 10-15 leading players. A conversation with some of the residential rooftop players revealed that the residential subsidies are getting delayed and signed contracts are getting cancelled. For quite a few ready-to-install contracts, materials for installations were already procured, which are now either sitting in their warehouses or stuck in logistics.

Leading rooftop C&I players expressed their concerns over the post-lockdown Operations and Maintenance (O&M) challenges:

1. C&I solar rooftop buildings will operate in a staged fashion with regard to their energy needs and hence, turning on the solar PV has to be staged too. But there is no clear insight to the best approach to activating small arrays at a time.

2. O&M services will pile up. How should one prioritise to maximise the revenue and keep the end-customer engaged and happy?

3. The availability of labor/staff for cleaning panels or regular O&M would be limited. How can one efficiently manage their available workforce?

Manual periodic cleaning impacted by lack of labor

One could sense that these problems have given an opportunity to the solar companies to rethink their cost structures, O&M, resource allocation etc. This lockdown helped create a space for solar companies to realise the inefficiencies with the O&M of solar plants.

NSEFI CEO, Subrahmanyam Pulipaka says- “COVID19, a black swan event, has a potential to change the entire paradigm of the rooftop business models in India. This will definitely pave the way for innovative business models and inculcating both cost effective and revenue inducing practices throughout the solar plant development ecosystem. Out of all the elements of rooftop plant commissioning, O&M which is often neglected will also be a direct witness of this paradigm shift and Indian rooftop sector will further move towards intensified digitisation of assets and their administration in the coming months.”

Solar companies in India have started to realise the need for building an O&M approach that’s futuristic in nature. Through speaking with several companies and via several webinars, the following requirement were noted:

1. Shift from the manual approach for O&M to an automated and predictive maintenance schedule to maximise the system performance and revenue.

2. End-customer engagement and awareness of their solar assets.

3. Focus on sustainability of the solar assets by building a data driven framework for: product selection, system design, dynamic production estimates, faster fault localisation and system degradation identification at early stages.

Companies around the globe have started using deep-data analytics and with the help of Artificial Intelligence and Machine Learning, they have started optimising their operations and maximising their revenue. John Deere was able to save $1 Billion by optimising their inventory2, Best Buy used deep-data analytics to redesign their stores to increase in-store experience3, UPS is utilising Machine Learning, Artificial Intelligence and Big Data to identify and predict problems in their logistics4, and the list continues.

Most of the solar companies in India currently use excel sheets to generate basic data analytics which only serves to manage reactive maintenance issues. All solar companies use data visualisation tools which provide fault alerts. These alerts are analysed by an engineer, followed by coordination with the on-site technician to localise the fault and rectify it. This leads to increased system downtime and lost revenue.

Data driven interventions by AI models can replace the conventional cleaning schedule and recommend when to clean the panels to maximise production and save water at the same time by optimising cleaning cycles.

Artificial Intelligence models help localise the faults automatically, learns system behaviour, predicts system’s performance and prescribes steps to maximise solar production, and hence revenue maximisation. Advanced AI models use dynamic pollution modelling and climate change factors to estimate realistic energy production, suggest dynamic cleaning schedules, accurately intercept shading losses, and monitor the electrical characteristics of your plant to predict its behaviour. AI can also help solve the problem of unidentified module degradation due to high temperature, Potential Induced Degradation , hot spots etc. by detecting them at a very early stage so that the bad guys could be taken out of the system and save the performance of the rest of the system from being affected.

References

https://economictimes.indiatimes.com/industry/energy/power/covid-19-impact-rooftop-solar-cos-worst-hit/articleshow/75002460.cms

https://www.sourcetoday.com/supply-chain/article/21865881/using-technology-to-improve-supply-chain-management

https://business.illinoisstate.edu/bestbuy/analytics.shtml

https://www.forbes.com/sites/bernardmarr/2018/06/15/the-brilliant-ways-ups-uses-artificial-intelligence-machine-learning-and-big-data/#61c5c6995e6d

https://mercomindia.com/mnre-solar-rooftop-program-guidelines/

https://mercomindia.com/solar-share-in-india-2/

NO COMMENT